article

FLSmidth Cement Automation Technologies revolutionizes plant automation with integrated electrical systems

Automation is a major contributor towards sustainable production and efficiency in modern cement plants. But what are the boundaries of automation today? Does automation start with the control system and end with high-level optimization? Or could it also include smart instruments, Intelligent Motor Control Centers (iMCCs), and a robotic laboratory? This would mean that plants could also business intelligence solutions to help make informed decisions at the plant level, as well as at the enterprise level. With the advancement of technology, the boundaries of automation are shifting.

Some equipment has lots of data to offer, but the present automation systems often fail to convert it into valuable information. Only when extra information is made easily available to plant operation and maintenance teams are the advancements in technology truly utilized and the investment justified.

Therefore, automation boundaries need to be extended to include electrical systems that have built-in business intelligence for plant management. This is a focus area for continued innovation and product development at FLSmidth.

Intelligent solution with knowledge built-in

In contrast to the simple “off-the shelf” products on the market which can be used for anything, ECS/ControlCenter v9 is developed specifically for the cement industry. This is not a general purpose “one size fits all” solution, but rather a highly specialized and tailor-made solution with a perfect fit for the Cement Industry. Not only developed by professional software programmers, but specified, tested, installed, and operated by some of the industry’s most senior machine and process specialists, ECS/ControlCenter v9 is now a product with expertise and experience built-in for the benefit of operators around the world.

ECS/ControlCenter v9

ECS/ControlCenter v9 is based on distributed architecture and designed for easy integration with numerous PAC hardware like Rockwell, SIEMENS & Schneider and MCC Intelligent Device like E300, SIMOCODE & Tesys T products to allow the user to freely choose the most suitable suppliers for the specific project. A configuration with motor control center intelligent Device from one supplier and process controllers from another is an example where ECS/ControlCenter v9 is highly advantageous as the overall integrating Automation and Electrical system.

Being a platform for control system solutions, ECS/ControlCenter v9 is an open environment that fulfils a wide range of requirements in terms of local regulations, group standardization and equipment functionality. The configurable environment of the platform with its high degree of flexibility makes for customer satisfaction.

In step with continuous development of hardware and software, ECS/ControlCenter v9 is known to utilize not only the most recent but also the most reliable technologies in control system solutions. Scalability is a distinguishing characteristic of ECS/ControlCenter v9.

ECS/ControlCenter v9 server can be used to control a single department with only a few hundred I/Os. The same server concept can later on be used to control additional production units or even the entire plant with high performance.

Dual server redundancy

The two servers are simultaneously active in all tasks and update each other with any configuration changes that might occur in either of them, to ensure consistent synchronous operation. A shutdown or critical failure in one of these servers will therefore not affect production. In contrast to traditional hot-standby solutions, where you can never really be sure that the stand-by server is actually ready for action, on ECS/ControlCenter v9 based systems you are never in doubt as both servers are always in operation – no switching over is required.

Server-client architecture

ECS/ControlCenter v9 is based on proven server-client architecture, where all operations are handled exclusively by the centralized servers. The servers function as central “hubs” for information, collecting process information from numerous process controllers and distributing it to numerous clients or ECS/Workplace used as operator stations.

Centralization of services provides a simple system with few complex devices and strong predictability because the communication with the process is constant, regardless of the number of operator stations, operators, and level of activity.

The servers also provide a powerful extension to the process controllers. In traditional DCS systems many performance-requiring functions are handled in the Process controllers – even if they are not very fit for the job. Often limited memory allows only for very short log horizons, and due to the simplicity of the engineering tools, applying advanced control is quite difficult.

ECS/ControlCenter v9 with Modern PCs and SQL data base are perfectly suited for logging large volumes of data with 1 second resolution for 1 yearlong horizon and providing effective user-friendly environments. ECS/ControlCenter v9 the process controllers are programmed to do what they do best: control the process – while the ECS/servers take care of what they do best, handling vast volumes of data and providing an efficient operator environment.

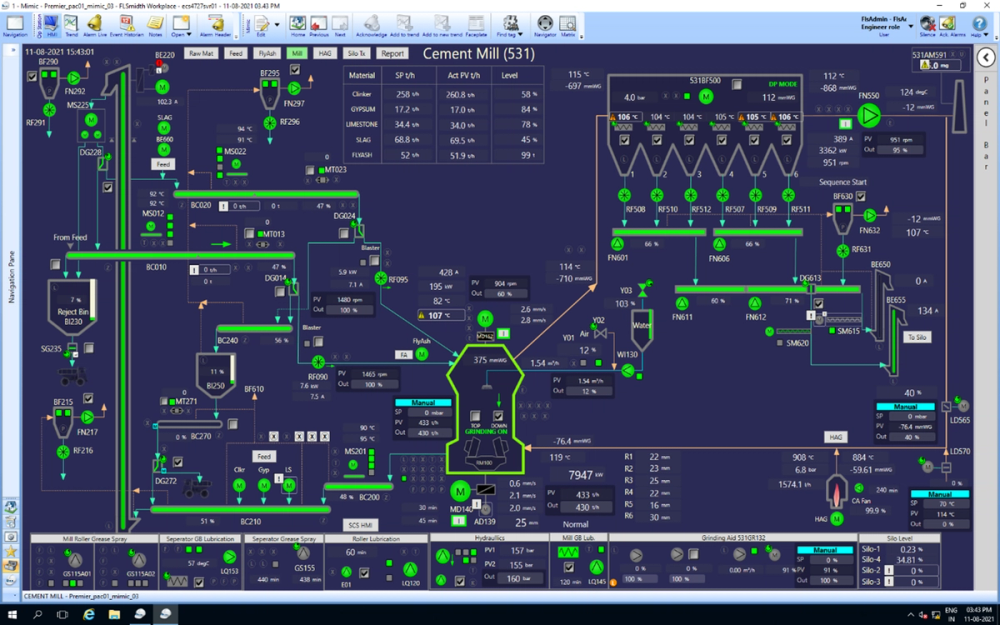

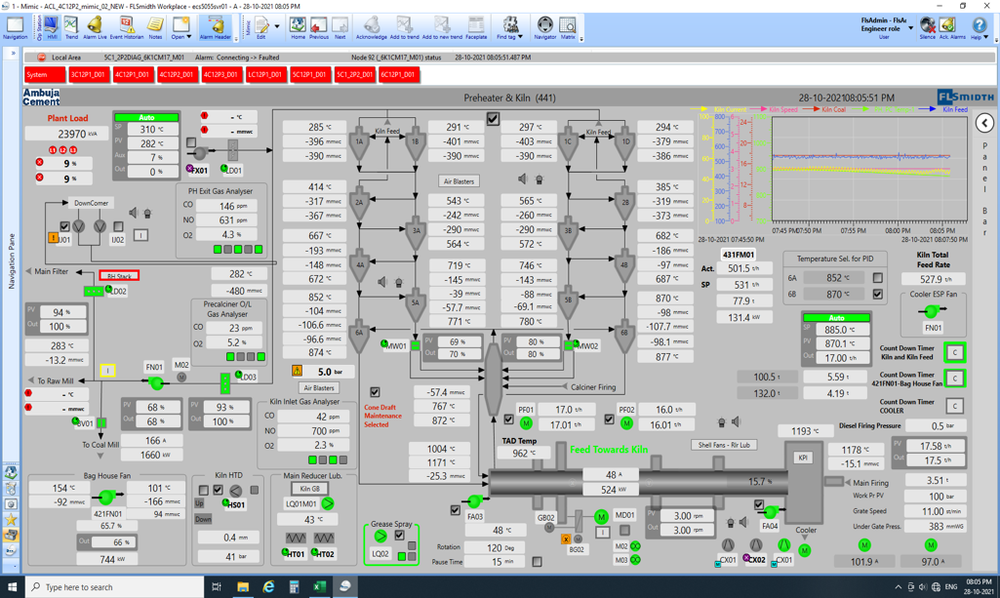

Operator’s and engineer’s user-friendly software solutions

Control room operators are often an underestimated asset to a production facility. In fact, operators play a key role in process control and supervision, so ECS/ControlCenter v9 provides an easy-to-use system for fast and reliable monitoring of the process conditions. The Operator Workplace is the gateway to all information about and interaction with the process. Everything needed to run the plant is available inside – and easy to use too. Not only does it provide a simple overview, enabling the operators to see clearly what has to be done, it also makes the interaction itself much faster, as every “knob” and “dial” is within easy reach.

In combination with our ECS™ and ACESYS™ Cement Control Library, the ECS/ControlCenter v9 Software Platform is the digital heart of plant operation: an advanced, reliable, adaptable and secure software platform that provides the foundation to control anything from machinery to full plants.

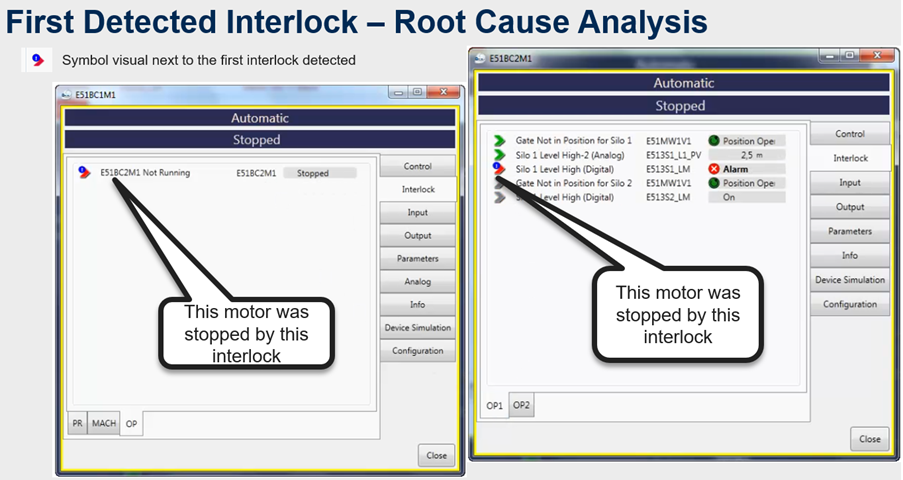

It is a known strength of FLSmidth to design efficient and clear process displays that help the operator keep the process running smoothly. The interlocks root cause analysis, advanced trending and reporting features of ECS/ControlCenter v9 enable much easier fault tracing and stable operation, as operators can easily understand the cause of tripping of any equipment.

Further improving ease of operation for Cement Plant operators, ECS/ControlCenter v9 displays are laid out with new equipment symbols based on Cement standards.

The entire PAC programming code and process interlocking had to be made to the perfection to avoid any surprises during commissioning. To address this, FLSmidth has several proven engineering and processing tools that ensure consistent and uniform structure of PAC programs. The structured output from these tools enables faster modifications, updates and troubleshooting during both commission and operation phases.

All I/Os and internal variables are named in a structured way in order to avoid the need for detailed knowledge of the physical addresses. Furthermore, a textual description is attached to all names to increase readability. The program is well documented with headlines and descriptions.

PAC (Programmable Automation Controllers or Process Controllers)

The process stations are based on fast and reliable PACs with numerous PAC hardware like Rockwell “L85E”, SIEMENS “S7 400 & 1500” & Schneider “M580”. For example, the PAC is from Rockwell Automation, Type CLX, normally 1756-L85E with the 40MB memory for the program. Each PAC covers a certain process area. In this area the PAC controls motors and valves and supervises alarms, any discrete signals and process measurements.

Improved availability is achieved by supporting redundant links to the process controllers. Process controller is equipped with multiple communication cards, the ECS communication drivers allow for automatic switching between the communication lines in the case of failure on ether switches, cables, connectors or communication cards. The ECS communication drivers are designed to optimize communication: by reading process information in blocks instead of individually and by differentiating between process values and supporting information.

The PAC’s are typically placed in the Electrical Load centers / Sub-station to avoid too many Fiber optic converter and to make the communication system more reliable in the plant.

Network

High availability of system is ensured with dual ECS servers and Ethernet Switches which provides a high degree of redundancy with respects to network communication in case of component and cable failures. Redundant network configuration is mainly used for continues communication between ECS/Servers and PACs. For larger ECS systems (dual configurations) redundant network configurations are recommended.

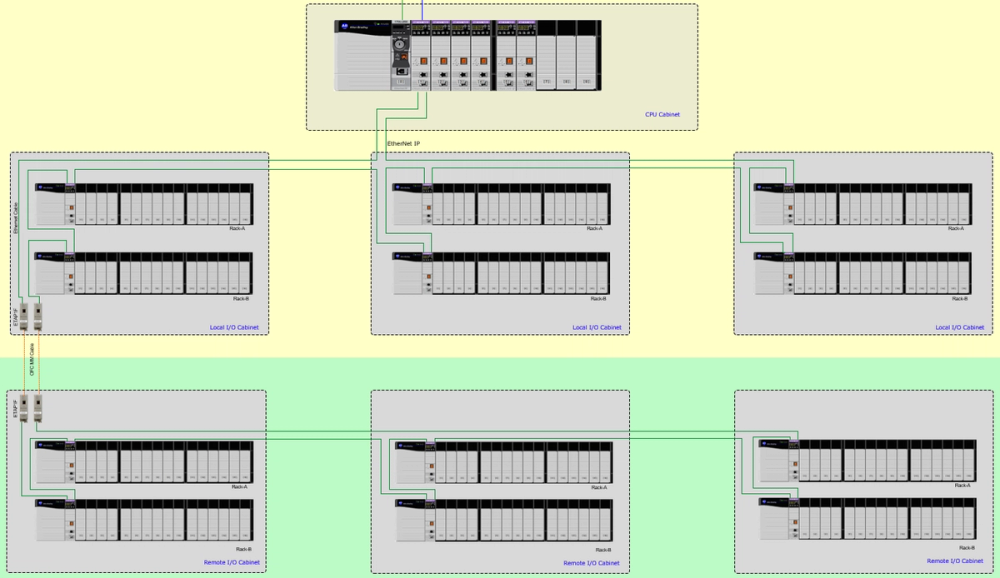

PAC to Field Network (Ethernet IP Ring Network)

The connections to and from the process are done through remote input/output system mounted in standard cubicles. Communication from the processor rack to any sub racks are over the EthernetIP in Ring Network. The philosophy of Ethernet IP Ring network remains same for PACs like Rockwell and Schneider. However, for SIEMENS it shall be Profibus or ProfiNet.

Typical architecture on Ethernet IP for PAC to IO Panels:

EtherNet IP is also used for connection to Motor Control Center Intelligent Devices, Sub-PAC system in the process department, Variable Frequency drives, it is also possible to install Modbus or Profibus in the Rockwell system. The Modbus or Profibus cards can be installed in any local CLX racks as needed.

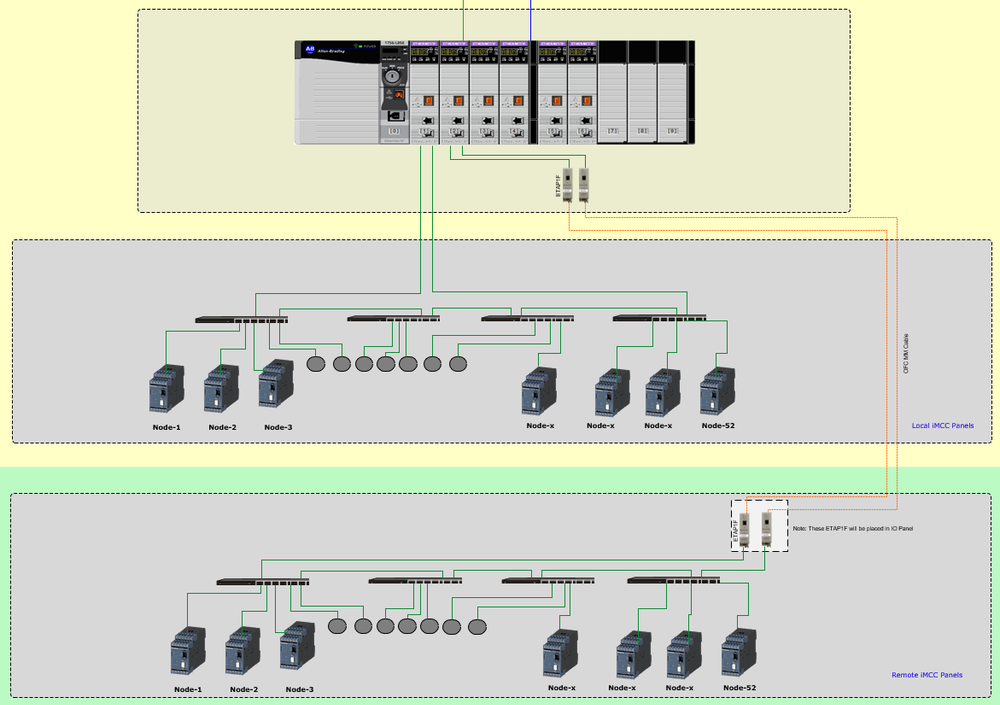

Typical architecture on Ethernet IP for PAC iMCC Intelligent Devices:

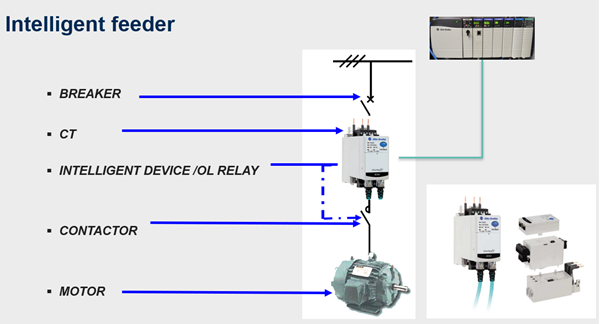

Intelligent Motor control Center

Generally, iMCC concept is perceived by many suppliers and user alike as the one, that:

- reduces cabling between MCCs and Control System

- reduces cabling hardware like cable trays, cable glands, cable termination material

- reduces load centre building sizes

- reduces time for installation

- reduces start-up time

These reductions certainly contribute to overall savings in project cost as compared with deploying conventional MCCs. Most Importantly Intelligent motor control centre allows a faster response to electrical issues like loose connections at power cables, phase loss, current imbalance, earth fault and process disruptions like material jamming, stalling, zero motion and helping to prevent motor damage and plant down time with more useful and decision-making warning and alarms at central control room operator station.

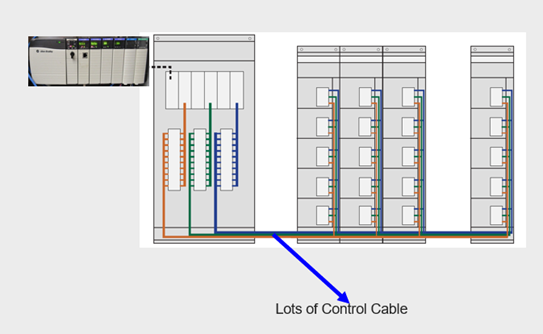

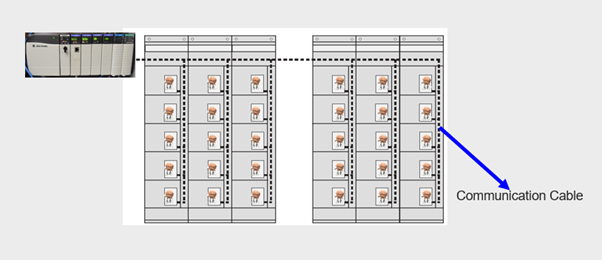

Conventional MCC vs Intelligent MCC

Conventional MCC and IO racks close

- IO rack next to MCC

- Communication bus till controller

- Separate Panel for IO racks

- Limited information

Intelligence in each feeder

- Intelligence & control wiring in each feeder

- Communication bus till controller

- Protective & diagnostic feature

Intelligent motor control centre design and solution is fully scalable for cement projects ranging from individual motor to a complete plant. Project specific options are available but not limited to like fixed/withdrawable configuration, single/double front, Incomer top or bottom cable entry/bus duct.

The Control feeder is a scalable controller for motor protection like fuse less design with MPCB/MCCB and fused design with SFU’s etc., it performs all tasks required to offer advantages in Scalability is achieved by selecting software modules (IUSYS) to perform protection, control or maintenance functions required by the user like DOL, RDOL, Damper Actuators etc., Hardware functionality may also be expanded with a wide range of additional I/O interfaces and additional hardwired interlocking like emergency stop, pull rope switches and Damper actuator torque switches to meet customized user demands control circuits.

IUSYS (Intelligent Unit System Standards)

FLSmidth’s IUSYS continuous research and long-term experience helps to develop seamless integration between plant control system and intelligent motor control center, VFDs, other Sub-Control System like Pfister® feeders etc., solutions in hardware and software technologies.

IUSYS leads the way with the first truly integrated Electrical and Control system, not only from the electrical and safety point of view but with the high capability for easy and reliable information distribution across the plant. IUSYS offers multiple possibilities for process operators, electrical and maintenance teams as well as plant managers not limited to access the desired information but also to change the desired set points across the plant provided user has the access rights.

IUSYS standards allows users to reuse engineering designs and practices to cut down development time, cost and to respond more quickly to plant/process demands and reduce downtime and maintenance.

IUSYS Blocks are integrated into our Cement Library ACESYS which makes our design unique and helps operator and electrical maintenance engineer to drill down to the root cause analysis from the same face plate.

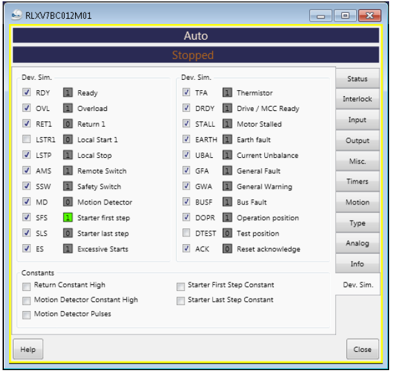

Testing / Factory Acceptance Test

A key stage in implementation of a new control system is testing the complete process interlocking at the FAT.

It is important to test the complete process interlocking through FLSmidth’s built-in device simulation function. For example, start and stop process simulations, which test whether process failures still result in safe operation of the equipment.

Device simulation is one of the unique features of ECS/ControlCenter v9, once the engineering/process interlocking is completed, entire process of the mill is simulated through device simulation mode with FLSmidth’s process engineers and Customer’s cement plant operators/process engineers. Entire plant was simulated and tested as per process sequence requirement including protection/safety interlocks. This helps & reduce time during commissioning of the plant.

During pandemic, most of our Cement customers couldn’t physically be present at FLSmidth Chennai to witness the test. This was not allowed to slow things down, however, with Customer’s cement plant operators and engineers participating though virtual sessions.

Customers also challenged to conduct the FAT for other equipment, such as the variable frequency drives (VFDs) and iMCCs through remote sessions. Again, FLSmidth has proven solution and has the capability and technology to establish a remote PAC connection, which is not limited to download, but also allows programming. This enabled us to complete the FAT to the satisfaction of customer and the project requirements. This was the main reason that there were no surprises during commissioning, and most of cement plants could commission the plant on time.

FLSmidth can also access the system remotely for monitoring and support, both during commissioning and thereafter, as needed.

Enabling better decisions

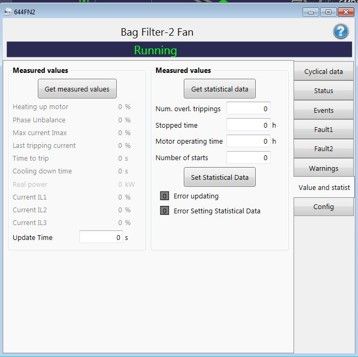

ECS/ControlCenter v9 with iMCC allows a faster response to electrical issues, such as

- loose connections at power cables

- phase loss

- current imbalances

- and earth faults

and well as to process disruptions such as

- material jamming

- stalling

- zero motion.

It therefore helps to prevent motor damage and plant downtime by providing more useful information, warnings and alarms to the central control room operator station, empowering better decision making.

These are possible because of networking technologies of Intelligent MCCs and ECS/ControlCenter v9 for which:-

Parameterization of intelligent motor feeders in MCCs are done from ECS/ControlCenter operator station

One Plant-wide network platform, Ethernet IP or Modbus TCP/IP with no third-party electronics in-between control system and iMCCs

Invoking of protective parameters and setting protective parameters from operator station

on the Ethernet IP / Modbus TCP/IP protocol for communication effectiveness

Faceplate technology in control system to facilitate complete motor management from operator screens without the need of third-party software.

Detection of early warnings from motors via Smart feeders to protect equipment and provide longer operating life.

Integration of motor control, alarm handling and process control under one cement program standard (ACESYS and IUSYS together)

Needless to say, (1) reduction in control cable, cable tray, space (2) deriving complete operational benefits and (3) simpler and maintainable network for higher reliability are possible ONLY if:-

- Intelligent MCCs are considered over conventional MCCs.

- ECS/ControlCenter v9 Control Platform to Integrate both Intelligent MCCs and Plant Control System

Unique vendor-independence

The ECS/ACESYS and ECS/IUSYS standard library is available for multiple PAC brands, including Siemens, Rockwell, Schneider allowing customers to select their preferred hardware for iMCC Intelligent device or even mix brands while benefitting from FLSmidth’s experience for example Rockwell Controller with SIEMENS intelligent Device. The ECS/ACESYS standard retains a uniform user interface across brands, appearing as one to the operators in the control room: a unique feature that adds to the system’s flexibility.

Protection Parameters monitoring at Operation Station: