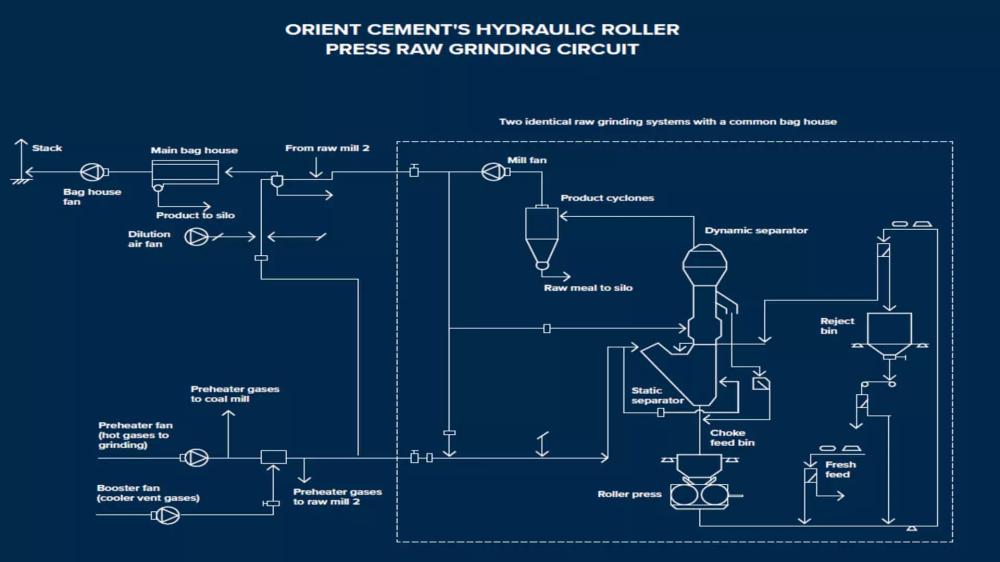

The limestone-rich belt of Karnataka in India is home to many cement plants, and the market for roller presses in the region is highly competitive. Given the numerous different options on the market, choosing the correct roller press solution and the equipment supplier can be daunting for plant owners. For Orient Cement, selecting the FLSmidth Cement Hydraulic Roller Press (HRP) has proven to be a cost-effective solution.

Finding the right solution

With a desire to optimise productivity, Orient Cement established selection criteria for evaluating a new roller press system for use in its 6,600 tonnes-per-day integrated greenfield plant. The three most critical objectives were high production performance, low power consumption, and grinding without adding water.

SHYAM ASAWA - Head of Projects at Orient Cement

Performance at Orient Cement

TABLE 1: The grinding system’s performance after the installation of two hydraulic roller presses.

Low power, no water

Shortly after the installation, it was evident that Orient Cement’s project objectives would be achieved, with all performance guarantees successfully delivered. As shown in table 1, actual production exceeded the intended capacity target by 6.5 percent – at a lower power consumption and with zero water consumption.

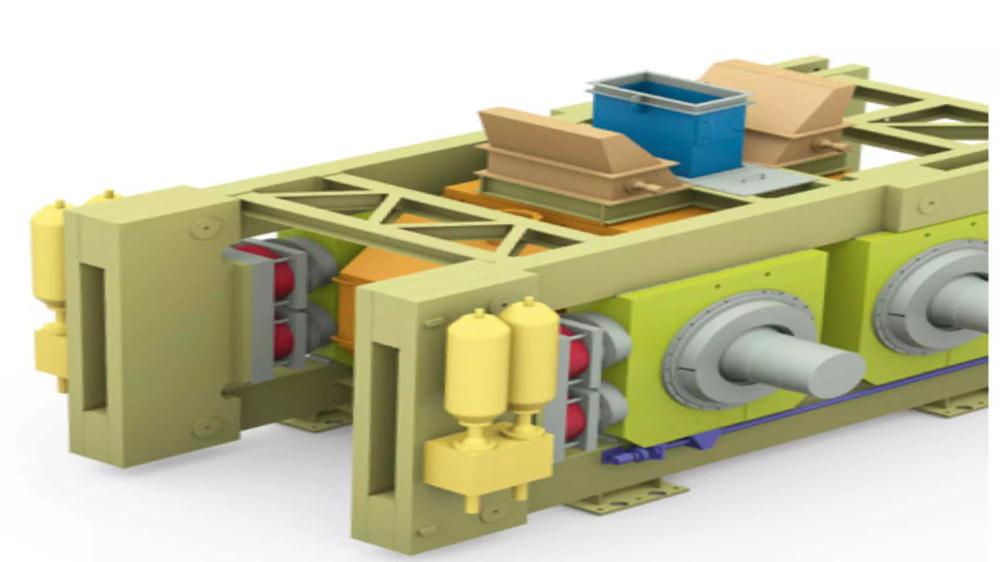

High-performance HRP

FLSmidth Cement's latest hydraulic roller press sets the bar with its efficient design and includes other noticeable improvements in performance:

- Solid forged rollers (no hollow shaft)

- Spherical roller bearings to accommodate angular misalignments

- Oil for bearing lubrication, bearing cooling, and filtering of foreign media

- Optimum roller Diameter to Width ratio

- Hinged frame for easy roller removal

These features enable the HRP to achieve high energy efficiency and contribute to a low total cost of ownership, largely due to its ease of operation and minimal maintenance costs.

When to consider an HRP system

- In regions with a high price per kW/hour

- In applications with an average feed moisture of less than 6%

- If water is scarce

- Where waste heat recovery power generation is important

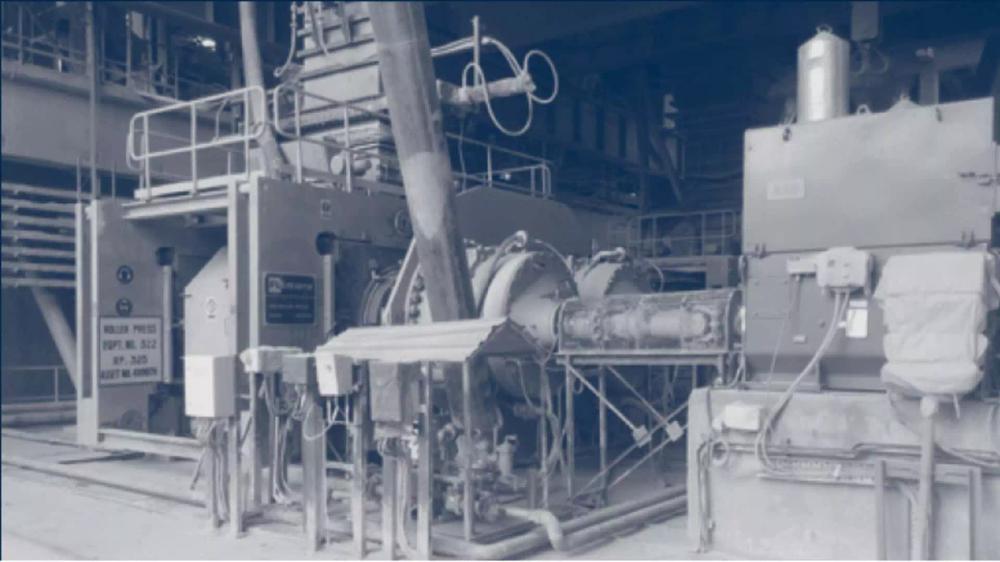

Today, the grinding system at the Karnataka plant is performing well. After the initial 10,000 hours, the conventional wear surface remains in good condition. No repair work has been required or performed thus far. This strong result is a testament to both the quality and durability of the equipment.

The HRP is suitable for upgrades and new installations. In some cases, an upgrade can more than double the capacity while reducing energy consumption by 30%

MR. ASAWA - Head of Projects at Orient Cement

The FLSmidth Cement Hydraulic Roller Press installed at the Karnataka plant

Orient Cement's Hydraulic Roller Press - Raw Grinding Circuit

Orient cement's hydraulic roller press specifications

- Raw material grindability: 12kWh/t at VRM shaft for product residue of 12% on 90 µm sieve

- Overall feed moisture: 4%

- Unit type: Roller Press HRP 3.0

- HRP dimension: 1920mm (diametre) x 1563mm (width)

- Installed power: (1600kW*2)

- HRP speed: 2m/s maximum

- Grinding pressure limit: 5500kN/m2 (maximum)

- Static seperator size: RPGS - 3150

- Dynamic seperator size: RARL 40

Since the successful installation of the HRP, Orient Cement has opened its plant doors to other cement producers to showcase the successful grinding solution and welcomed any discussion regarding its positive experiences.

.png?w=1080&q=80&auto=format)

.jpg?w=1080&q=80&auto=format)