article

Premier Cement sets solid foundation for digitalization with ECS/ControlCenter v8

Do you worry about your plant reliability? Sustainability? Cybersecurity? Finding skilled operators? With our latest ECS/ControlCenter v8 process control software platform, you don’t have to. As a cement producer in Bangladesh, Premier Cement, is finding out.

Digitalization: a critical enabler of operational improvement

Premier Cement is one of the leading cement producers in Bangladesh. Maintaining its market position is a constant concern. Adopting the latest digital technologies is a key element in the company’s strategy of continuous improvement to achieve operational excellence.

In the latest step on its digital journey, Premier Cement has commissioned the ECS/ControlCenter v8 process control software platform on two OK cement mills:

- 460 tph capacity OK 71-6 mill at its Dhaka plant

- 280 tph capacity 56-4 mill at its Chattogram location

Laying a strong foundation for digital success

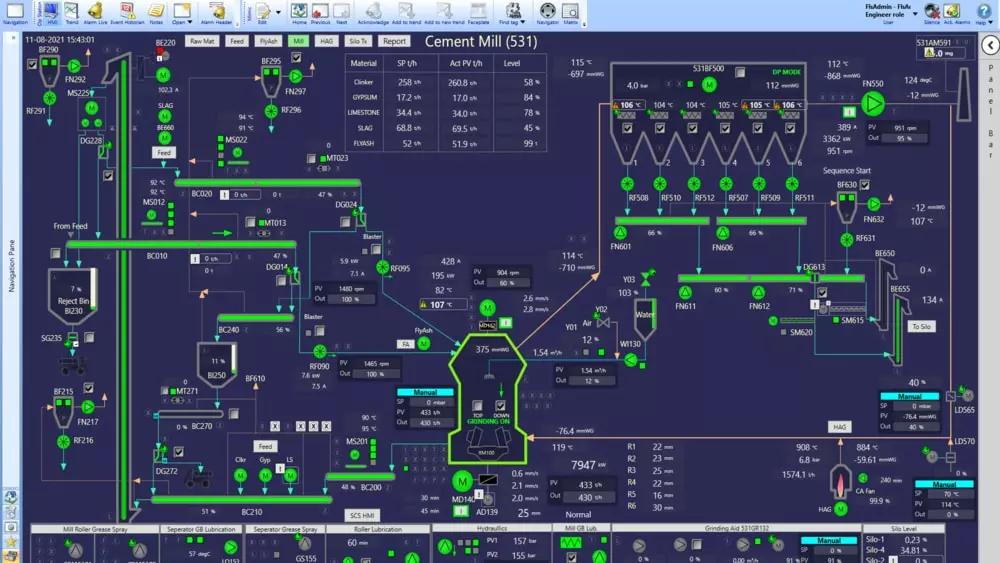

In combination with our ECS/ACESYS™ Control Library, the ECS/ControlCenter v8 software sits at the digital heart of plant operations: an advanced, reliable, adaptable and secure platform that provides the foundation for controlling anything from individual machines to full plants. In doing so, it helps ensure equipment runs consistently and at optimal conditions, while reducing the risk of operator error.

Designed to be hardware agnostic, the system collects and structures data from PLCs as the basis for digital optimization. Its advanced HMI/SCADA functionality then empowers optimal supervision and control of all departments in large grinding facilities, such as those at Premier Cement.

The system also includes local control panels at the equipment, such as hydraulics, gearboxes and hot air generators – a feature the operators at Premier Cement appreciated. These panels enable key data, including trends, alarms and reporting tools, to be viewed on an operator display on the machine. It’s also possible to operate the machine locally. This functionality helps expedite and simplify maintenance.

IMAM TANVIN ALAM - Head of Project Management at Premier Cement

Extending automation intelligence for reduced downtime

During implementation of the ECS/ControlCenter v8 software, the PLC programming code and process interlocks had to be completed to perfection to avoid any surprises during commissioning. To address this issue, we have several proven engineering and processing tools that ensure consistent and uniform structuring of PLC programming. The structured output of these tools provide enables faster modifications, updates and troubleshooting during both commissioning and operation.

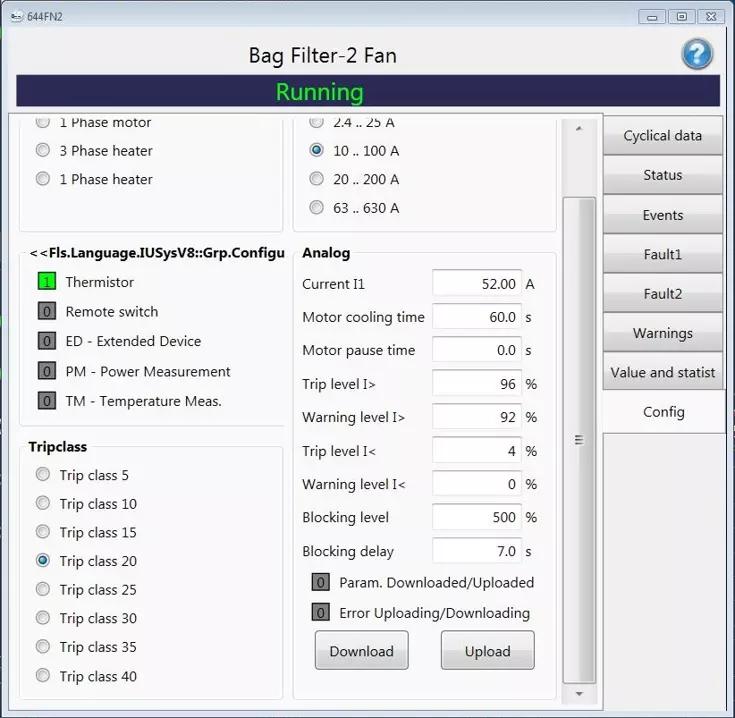

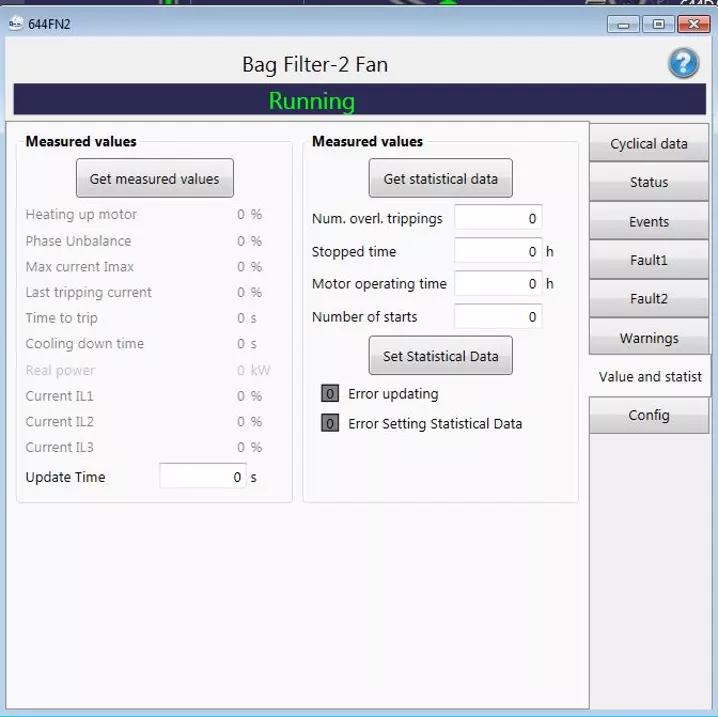

As part of its digital strategy, FLSmidth Cement and Premier Cement has combined intelligent motor control with ECS/ControlCenter v8.

“Intelligent overload relays offer lots of data, but automation systems often fail to convert that data into usable information,” explained Mr Alam. “By integrating ECS/ControlCenter v8 with intelligent motor control, we can respond faster to electrical issues, such as loose connections, phase loss, current imbalances, and earth faults, as well as processing disruptions, such as material jamming, stalling, and zero motion.”

The end result? “It helps to prevent motor damage and plant downtime by providing more useful information, warnings and alarms to the central control room operator station, empowering better decision making,” concluded Mr Alam.

Device simulation reduces commissioning time

Device simulation is one of the unique feature of ECS/ControlCenter v8. When the engineering/process interlocking phases are completed, “this feature enables the process to be simulated and tested as per process sequence requirements – including protection/safety interlocks,” said Rizwan Sabjan, Head – Regional Sales Enablement. “This helps to reduce time during commissioning of the plant.”

About Premier Cement

Starting cement production in 2004 with an initial capacity of 0.6 million tpy, Premier Cement is one of the fastest-growing cement companies in Bangladesh, targeting cement production capacity of 8 million tpy. The company’s cement has helped to build a number of strategically important projects, including the Padma bridge, Rooppur nuclear power plant and Karnaphuli tunnel. https://www.premiercement.com/