article

Successful transfer of waste heat over 350m reduces carbon footprint

Cemento PANAM has achieved fantastic success reducing its carbon footprint and fossil fuel bill by implementing a 350 m long waste heat bypass system, using waste heat from the cooler to dry materials in its cement mills.

Cemento PANAM in the Dominican Republic is a new cement plant that prides itself on its green credentials. Situated about an hour from Santo Domingo in San Pedro De Macoris province, the plant is capable of producing 1 million tpy of cement (750 000 tpy of clinker) and is designed to achieve particulate emissions five times lower than the country’s regulatory limit at 30 mg/m3.

With the environment in mind, Cemento PANAM was keen to discover if it could reduce its fossil fuel use by utilising waste heat from the clinker cooler to dry materials in the finish mills. At the time, the vertical roller mills were employing a hot gas generator to heat up/dry off the materials in the mill. And although natural gas is relatively clean, it is still a fossil fuel – and an expensive one at that.

Making use of waste heat

Like so many plants, waste heat from Cemento PANAM’s cooler is typically released into the atmosphere. The possibility of turning this waste into a valuable resource was an idea that fit well with Cemento PANAM’s sustainability mindset and would also significantly reduce costs. It was not without its challenges though.

“We contacted FLSmidth Cement because we had seen that this is something they have a lot of experience with and we wanted to know if it could work for us,” explains Arnoldo Alonso, Plant Manager, Cemento PANAM “We had faith in the technology, but doubts about the practicality of the system given that the finish mill is 300 m away from the cooler. How do you transfer heat over such a distance?”

This was the furthest distance FLSmidth Cement had ever tried to take waste heat – perhaps the furthest that any cement company has attempted to do it. The concern, of course, was that the heat would be lost as it travelled down to the finish mills, rendering it relatively useless by the time it arrived. In order to make it work, FLSmidth Cement had to bring in its modelling experts.

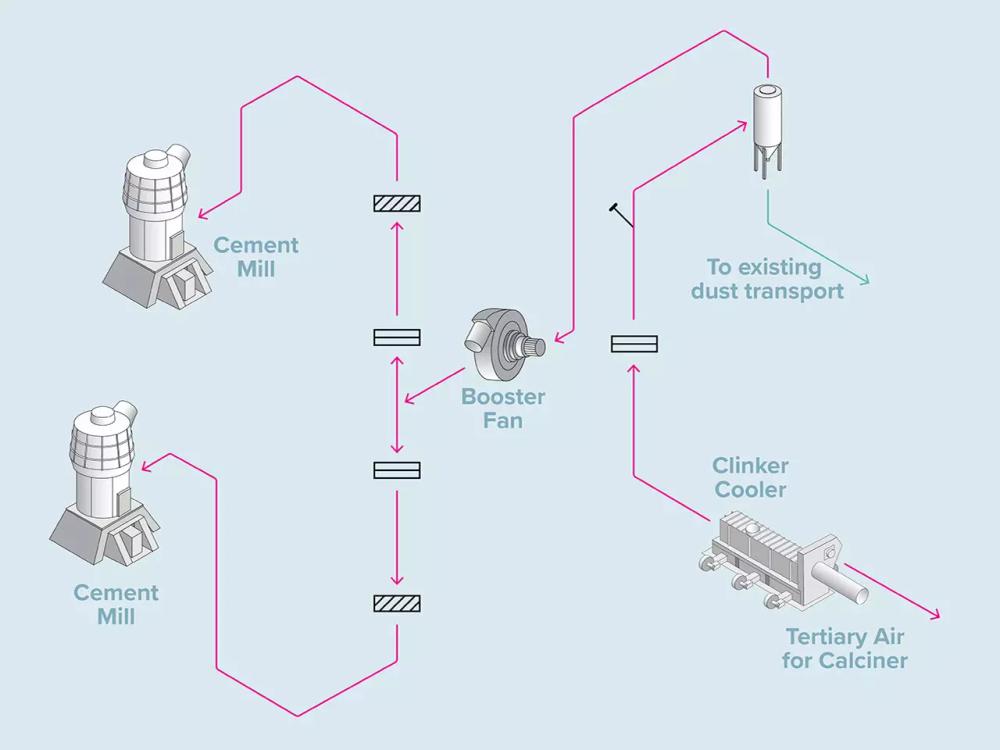

The waste heat recovery system also makes use of the existing kiln ID fan and the cooler excess air fan. All three fans are moving in different directions and are carefully balanced to get the right amount of flow in the right direction.

Managing heat loss

“We had two main concerns: heat loss and velocity,” explains Srdan Nisic, Sales Manager - Projects & Retrofits, FLSmidth Cement. “If the velocity is too low, the particles in the gas mix will drop. If the duct fills up with particulates, the velocity increases and then you get problems with wear. We used CFD modelling and other simulation tools to work out the specific filling degree for the duct, the perfect duct diameters, and where to put the booster fans to ensure optimum gas velocity to conserve heat and minimise problems with wear. We also made sure that the cyclone was designed to minimise particulates in the gas stream. It was one of those projects where we had to look at the big picture as we were defining the small details.”

Working on a project like this that is entirely unique, it is important to maintain constant communication. One of the plant’s concerns was that utilising heat from the cooler might take heat away from where it was already being used as tertiary air for the kiln. In answer to this, FLSmidth Cement added in another pressure point to ensure there was continuous pressure on the waste heat recovery system so as not to ‘steal’ hot gasses that were intended for the kiln.

Accommodating different moisture levels in the cement mill

Another issue was that the plant manufactures two types of cement, 27.5 and 35, which have different levels of moisture in the raw additive components. With two finish mills in operation, there are various operating scenarios:

- 27.5 and 27.5

- 27.5 and 35

- 35 and 27.5

- 35 and 35

- 27.5 and the other mill is down

- 35 and the other mill is down

In all scenarios, the same amount of heat is being sent from the cooler.

“The 27.5 cement has a higher moisture content than the 35 cement,” says Arnoldo Alonso, Cemento PANAM. “FLSmidth Cement calculated that if both mills were making 27.5 cement, the heat from the cooler would not be sufficient and the hot gas generator would need to be used. On the other hand, if one of the mills is down, the heat from the cooler is too much so they worked out a way to reduce the temperature by introducing more fresh air into the duct.”

With all of the calculations made, the project was ready to go ahead. FLSmidth Cement's scope of supply included:

- Process design

- Plant layout

- Cyclones

- Dividing gates

- Slide gates

- Fresh air damper

- Booster fan

The ducting was built locally based on the FLSmidth Cement detailed design.

The waste heat recovery system also makes use of the existing kiln ID fan and the cooler excess air fan. All three fans are moving in different directions and are carefully balanced to get the right amount of flow in the right direction.

Installation and commissioning

Cemento PANAM carried out the installation work.

“It was quite a simple project in that respect. Most of the work could be carried out while the plant was in operation, with just a short 2-day outage while we made the final connection with the cooler and with the finish mill,” says Arnoldo Alonso. “The new system has integrated very well with our existing equipment, and it is easy for the operators to use.”

“Within 15 days of start-up, the system was fully commissioned and achieving our performance guarantees,” adds Srdan Nisic, FLSmidth Cement. “Heat loss from the cooler to the finish mill – over a distance of 350 m – is just 50˚C. It is actually outperforming our expectations.”

As a result of implementing this waste heat recovery system, Cemento PANAM is saving hundreds of thousands of dollars per year on fossil fuels use and has achieved a significant reduction in their carbon footprint.

“We are very happy with the outcome of the project and would encourage other cement manufacturers to consider if they can do the same. If we can use waste heat from the cooler 300m away at the finish mill, imagine what you can do,” says Arnoldo Alonso, Cemento PANAM.