article

Les Ciments du Sahel (CDS) - Kirene, Chinese EPC Supplier, and FLSmidth Cement Redefine Cement Production with ECS/ControlCenter™ solution

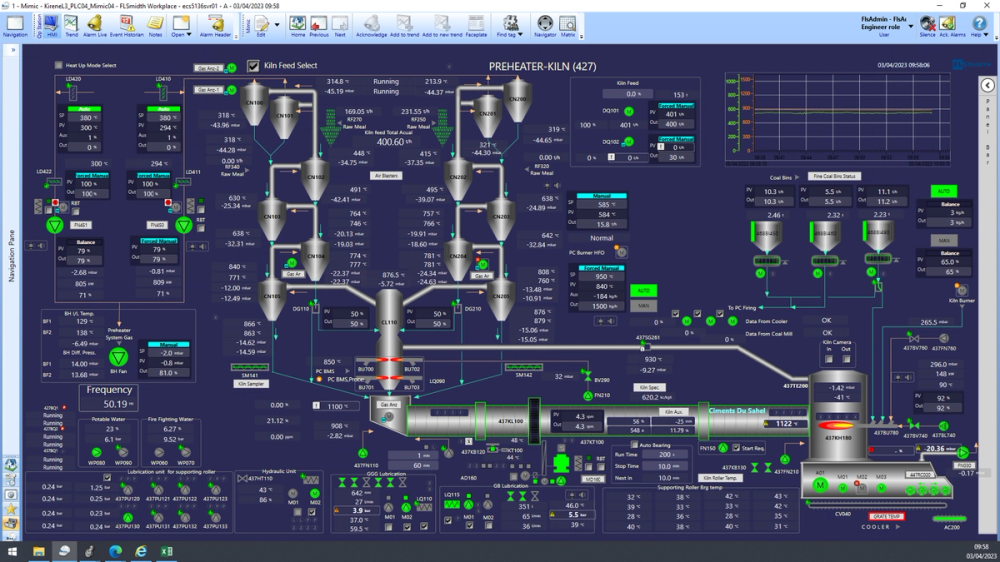

In Senegal’s competitive cement market, CDS Kirene Cement needed a breakthrough. Their solution came through a strategic partnership with Chinese EPC Supplier and FLSmidth Cement to deploy ECS/ControlCenter — the most advanced automation platform in cement manufacturing. The result is a fully unified, cyber-secure production facility that sets a new benchmark for efficiency, scalability, and innovation.

The Challenge: Unifying Three Lines Under One Brain

Kirene’s existing Lines 1 and 2 operated on fragmented systems, creating inefficiencies. For Line 3, the goal was ambitious: integrate all three production lines under a single, intelligent automation platform while future-proofing operations. Success hinged on seamless collaboration— Chinese EPC Supplier’s engineering expertise, FLSmidth Cement’s cutting-edge control systems, and Kirene’s operational vision had to align perfectly.

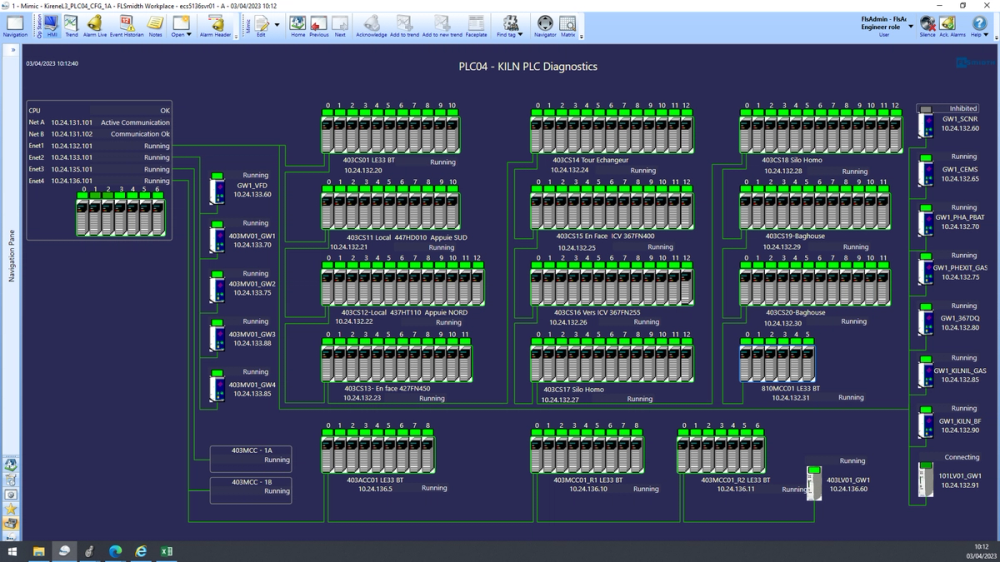

The success of this project hinged on the synergy among FLSmidth Cement, Chinese EPC Supplier, and CDS. Through meticulous planning and constant communication, the teams synchronized efforts across design, implementation, and commissioning phases. This collaborative spirit extended to a comprehensive analysis of the plant’s existing network infrastructure, identifying vulnerabilities and outdated components. By replacing most of the networking hardware with modern, secure solutions, the partnership fortified the plant’s cybersecurity, making it resilient against potential cyber threats and ensuring uninterrupted operations in an increasingly digital landscape.

Mr. Oumar Diallo, CDS Kirene Cement

The Game-Changer: ECS/ControlCenter

ECS/ControlCenter platform transformed the plant into a data-driven powerhouse. Real-time process optimization, powered by instant diagnostics and interlocks, drastically reduced troubleshooting time. cybersecurity measures—including role-based access, secured networks, and modernized hardware—eliminated vulnerabilities. Cement-specific intelligence, enabled by pre-configured ACESYS libraries, ensured seamless integration, while remote monitoring kept the project on track even during COVID-19 lockdowns.

Our ACESYS (Cement Specific) library ensures seamless integration with cement-specific processes, enhancing overall performance.

✔ Rapid trip diagnostics with detailed interlock insights via faceplates

✔ Advanced cybersecurity with role-based access, encrypted communications, and a hardened architecture

✔ Intuitive, standardized controls to minimize specialist dependency

✔ Our ACESYS library for seamless integration with cement processes

Pandemic Pivot: Virtual Testing Saves the Day

When travel bans halted traditional Factory Acceptance Testing (FAT), we revised the rulebook. The team leveraged virtual PLC simulations to rigorously test variable frequency drives (VFDs), motor controls, and safety systems. Kirene’s operators participated in live remote validation sessions, ensuring flawless commissioning. The outcome? Zero delays—a remarkable achievement for a project of this scale.

- Virtual PLC simulations tested VFDs, motor controls, and safety systems.

- Kirene’s team joined live remote validations, ensuring flawless commissioning.

- Result? Zero delays—a first for a project of this scale.

Operators Became Data Heroes

With intuitive dashboards and predictive analytics, Kirene’s team transitioned from reactive problem-solving to proactive optimization. Insights from Intelligent Motor Control Centers (iMCCs) enabled predictive maintenance, preventing unplanned downtime. Smart alarm prioritization allowed operators to focus on critical issues first, streamlining decision-making.

The Impact: Enhanced Reliability, Security, and Efficiency

The implementation of ECS/ControlCenter™ has transformed operations at Kirene. The plant now experiences no unplanned stoppages, thanks to faster and more effective troubleshooting capabilities. Operators are empowered to handle issues independently, reducing reliance on specialists and improving operational efficiency. The upgraded and new system also provides robust cybersecurity measures, ensuring the plant is well-protected and future ready. Furthermore, the use of simulation during commissioning has lowered commissioning costs by minimizing risks. “ECS/ControlCenter™ has revolutionized our plant’s performance and security, laying a solid foundation for sustainable growth,” said Mr. Oumar Diallo.

✔ No unplanned downtime with faster issue resolution

✔ Empowered operators, reducing the need for specialist intervention

✔ Fortified cybersecurity, ensuring future-ready operations

✔ Lower lifecycle costs through simulation-driven commissioning

A Blueprint for the Future

This project proves that collaboration + innovation = transformation. As global cement demand grows, Kirene’s success offers a replicable model: integrate, automate, and secure.

.png?w=1080&q=80&auto=format)