article

Cooler Than Ever: How Shree Cement’s Mega Cooler Is Redefining Efficiency and Energy Recovery

In December 2023, Shree Cement’s newest cement plant began operations in Nawalgarh, Rajasthan. According to the Guiness Book of World Records, the plant is home to the world’s largest pyro system, producing more than 13 500 tpd of clinker against performance guarantees of 11 500 tpd. This historic performance would not be possible without the Cross-Bar® Cooler from FLSmidth Cement, which maintains impressive productivity and efficiency while also contributing to Shree Cement’s sustainability goals through waste heat recovery that amounts to around 8 MW of power generation.

The Cross-Bar Cooler is no stranger to success, having achieved high throughputs and consistent results at multiple locations worldwide since its introduction in 2010. But in Nawalgarh, that performance has been levelled up again with average daily throughput of 13 695 t of clinker – a true world record. To achieve this high level of productivity, FLSmidth Cement had to build big – with a 325 m2 grate area incorporating 24 grates in width and 80 grates in length.

Though some equipment struggles to scale up, the Cross-Bar Cooler does not have this problem. As a modular system, it is easy to tailor to the size required for each application, and it doesn’t lose any efficiency as it expands. The static grate enables a bed of clinker to build up, protecting the grates from wear. The horizontal cross bars, raised about 90 mm above the grate line, move in a shuttle motion, effectively conveying, mixing and shearing the clinker, giving it sufficient exposure to the cooling air. The larger the grate area, the more opportunity for clinker to come into contact with cooling air – which is why large throughputs are not only possible but simple.

Design highlights

The Cross-Bar Cooler benefits from a number of unique features that enable high throughputs like those seen at Nawalgarh without succumbing to the usual problems that disrupt operation – like snowmen and red rivers.

ABC Inlet® Technology

Ordinary fixed inlets use air blasting to destroy snowmen – agglomerations of clinker – in the cooler. These air blasters are built into the side walls and back of the cooler inlet and usually have a blast radius of just half a metre. Unfortunately, that’s not enough to prevent snowmen forming in the centre of the inlet – particularly in larger coolers. The ABC Inlet uses a patented in-grate design that pushes compressed air up through the grates, blasting agglomerations. Plus, rather than waiting for snowmen to form and then dealing with them, the ABC Inlet uses pressure sensors to detect when build-up is starting to occur and the automated blast control system reacts accordingly, increasing blast frequency to disperse the clinker and prevent further agglomeration. This proven system effectively prevents snowmen from forming and was a major reason why Shree Cement opted for the Cross-Bar Cooler in this plant.

This proven system not only prevents snowmen from forming but also facilitates more efficient thermal exchange, enabling heat to be recovered and reused in the pyro process.

Heavy Duty Roller Breaker (HRB)

Clinker doesn’t arrive in the cooler in a uniform size and shape – and sometimes large clinker boulders can be in excess of 1 m diameter, creating a blockage in the cooler that requires a shutdown to clear. However, the Cross-Bar Cooler at Nawalgarh is equipped with a Heavy-Duty Roller Breaker (HRB) capable of destroying clinker boulders up to 1.5 m without disrupting operation. It works through a combination of cleverly designed toothed transport and crushing rollers with reversible crushing rolls that easily grip and break down boulders, preventing jamming even with very large boulders.

The HRB operates at a lower speed than the traditionally used hammer crusher, delivering powerful impact without the high-speed blows that can cause wear to the rest of the cooler body. Maintenance is minimal and the wear life of the rollers is expected to exceed 3 years, with 5-year wear life being seen in other applications.

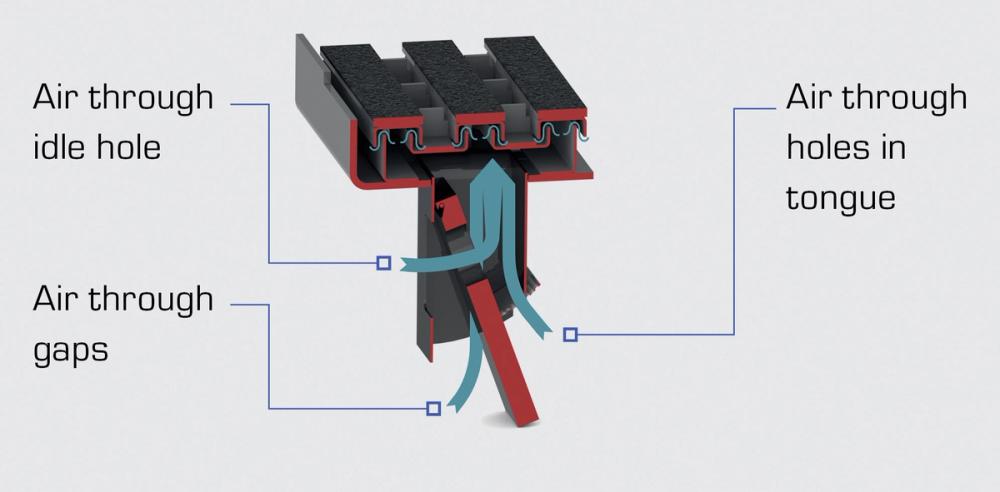

Mechanical Flow Regulators (MFRs)

MFRs optimise air flow to maximise cooling and recuperation efficiency. Acting as a flow limiter in places where a lack of resistance causes more air flow than is needed – such as through the coarse clinker layer – the MFRs are a money- and energy-saver, preventing waste while ensuring efficient cooling. Best of all, mechanical flow regulators operate automatically, so the team at Nawalgarh won’t have to think about optimising air flow – it will all be taken care of.

Energy recovery

Shree Cement is focused on energy efficiency and sustainability, so wanted to recover as much hot air from their clinker cooler as possible. The configuration of the Cross-Bar Cooler allows a significant portion of the cooling air to be recirculated back into the pyro process instead of being wasted.

Instead of allowing relatively low-grade heat to dissipate into the atmosphere, this energy is recaptured and reused in the process. A portion of the recirculated air is directed to the cooler recuperation zone and to the preheater stages, where it boosts the temperature of incoming raw meal and reduces the fuel demand in the kiln system. The remaining part of the recirculated air is directed to the cooler cooling zone and to WHRS (Waste Heat Recovery Systems) to improve the power generation. Excess air volume and temperature are reduced dramatically – from 1.28 kg/kg at 355 °C to just 0.15 kg/kg at 164 °C – which reduces energy loss and helps optimise WHRS performance. The recirculation also helps maintain high secondary and tertiary air temperatures, supporting stable kiln and calciner operation.

From a sustainability perspective, this approach contributes directly to lower CO₂ emissions, limits the usage of water injection in cooler, improves alternative fuel utilisation, and creates a leaner, more circular use of thermal energy within the plant — all aligning with Shree Cement’s decarbonisation and energy efficiency goals. With approximately 8 MW of power recovered from the cooler alone — part of a plant-wide WHR capacity approaching 18 MW — Shree Cement is making tangible progress toward its goal of energy self-sufficiency.

Optimal results and reliability

From delivery to commissioning, this project took just 11 months, and the cooler experienced no issues during start-up. The plant team eased into things, beginning with just 5000 tpd through the cooler and quickly increasing to 11 500 tpd and then beyond.Now, the cooler regularly exceeds 13 500 tpd and has experienced no issues since start-up in December 2023.

“The cooler can handle anything. We’ve been running beyond performance guarantees for more than a year without any issues and in that time, we have varied the input of fuels and raw materials with no disruption in the cooler. We’ve been very impressed with both its performance and its reliability,” says Rajiv Sadavarti, Head Performance Excellence, Shree Cement. In fact, the company has been so happy with the line at Nawalgarh that they have ordered two more identical lines for other plants to assist with their goal of 80 million t capacity by 2028.

The performance of the Cross-Bar Cooler at Shree Cement’s Nawalgarh plant is a clear example of how cooler design can support both high output and efficient, reliable operation. By scaling up without compromising stability or energy recovery, the cooler has helped the plant meet ambitious production goals while also supporting long-term sustainability targets. For operations looking to balance productivity with efficiency, it offers a compelling model of what’s achievable with the right technology.

This article first appeared in the September 2025 issue of World Cement.