article

Boosting Uptime, Efficiency and Cyber Resilience with Our ECS/ControlCenter™ v9 Advanced Automation Solution

The Karbala Cement plant in Iraq faced operational challenges due to an outdated control system that resulted in frequent unplanned shutdowns and a dependence on specialised technicians. Addressing these issues, the plant partnered with FLSmidth Cement to implement our ECS/ControlCenter™ v9, automation platform, improving reliability and efficiency, eliminating unplanned downtime, fortifying the plant's security, and laying the foundation for sustainable growth.

The Challenge: Aging Systems Hinder Performance and Security

At Lafarge Iraq's Karbala cement facility an outdated Polcid control system, built on Rockwell RSview with Siemens I/Os on Profibus DP, created significant operational challenges. The plant experienced frequent unplanned shutdowns, which were difficult to diagnose and resolve, leading to costly downtime. Additionally, the system’s complexity meant that even basic troubleshooting required specialised technicians, slowing down operations. Compounding these issues, the lack of standardised cybersecurity measures left the plant vulnerable to growing digital threats. “The old system was sluggish, prone to failures, and lacked modern security measures. Our team struggled to pinpoint issues quickly,” said Mr. Salah Hassanein, Instrumentation & Projects Lead at Lafarge Karbala Cement.

The Solution: A Robust, Cement-Tailored Automation Platform

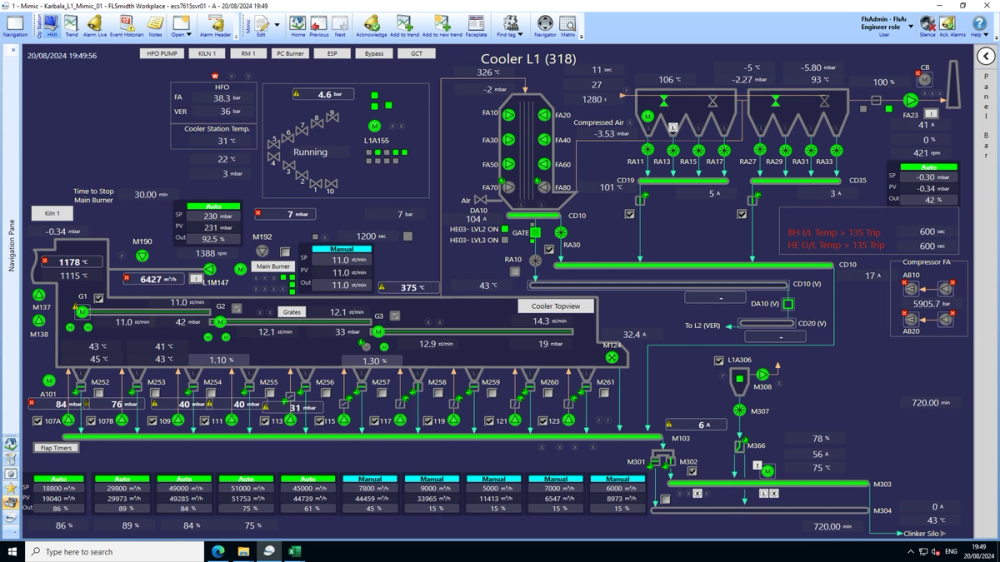

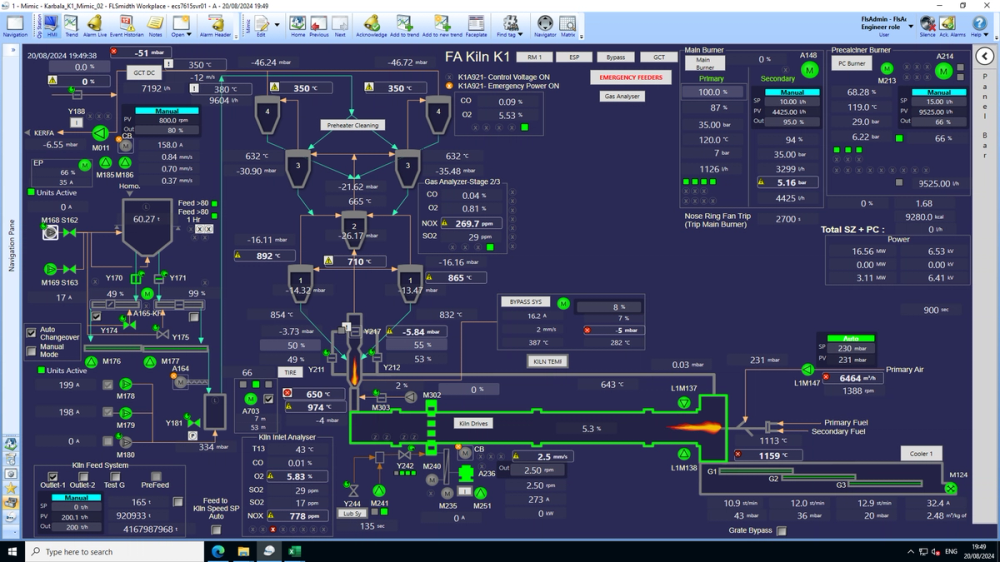

The Karbala plant partnered with FLSmidth Cement to implement our state-of-the-art ECS/ControlCenter™ v9, automation platform. Designed specifically for the cement industry, this solution enables rapid trip diagnostics by providing detailed interlock insights directly through faceplates, streamlining issue resolution. It also incorporates advanced cybersecurity features, including role-based access, encrypted communications, and a new network architecture, to protect against digital threats.

The platform’s intuitive, standardised controls reduce the need for specialist intervention, empowering operators to manage operations efficiently. Additionally, FLSmidth Cement’s cement-specific ACESYS library ensures seamless integration with cement processes, enhancing overall performance.

Mr Salah Hassanein, Instrumentation & Projects Lead at Lafarge Karbala Cement

Engineering Precision: A Seamless, Budget-Friendly Overhaul

The upgrade was meticulously planned to minimise disruption and costs. Existing hardware, such as I/Os and panels, was retained to reduce expenses, while outdated PLCs and communication cards were replaced with modern, secure Siemens 1500 Controllers. The PLC logic was rewritten to ensure standardisation and efficiency, eliminating inconsistencies in the system.

By leveraging the ECS/ControlCenter platform's simulation mode, the team tested and refined operations before deployment, reducing risks during commissioning. “We revamped the tag database, standardised the logic, and bolstered cybersecurity while keeping costs low by reusing hardware. It was a challenging yet highly efficient transformation,” noted Prasath Kumar, Engineering Manager at FLSmidth.

User interface for ECS/ControlCenter™ 9 for coolers

The Impact: Enhanced Reliability, Security, and Efficiency

Implementing the ECS/ControlCenter™ v9 platform has transformed operations at Lafarge Karbala. The plant now experiences no unplanned stoppages, thanks to faster and more effective troubleshooting capabilities. Operators are empowered to handle issues independently, reducing reliance on specialists and improving operational efficiency. The upgraded system also provides robust cybersecurity measures, ensuring the plant is well-protected and future-ready. Furthermore, the use of simulation during commissioning has lowered lifecycle costs by minimising risks. “ECS/ControlCenter™ has revolutionised our plant’s performance and security, laying a solid foundation for sustainable growth,” said Mr. Salah Hassanein.

It was a remarkable experience serving Karbala Cement, where I received exceptional support and understanding from the site team, which greatly contributed to the successful commissioning. The Karbala cement plant recognises the efforts of commissioning specialist Riyaz Abdullah Mohammad for earning well-deserved appreciation

User interface for ECS/ControlCenter™ 9 for kilns

Ready to Modernise Your Plant?

If your plant is grappling with outdated systems or cybersecurity vulnerabilities, FLSmidth Cement’s ECS/ControlCenter™ automation platform offers a proven solution to enhance uptime, efficiency, and resilience.

.png?w=1080&q=80&auto=format)