article

Modernizing Water Treatment: How SPCC's Bisha plant Seamlessly Upgraded Automation with our ECS/ControlCenter™

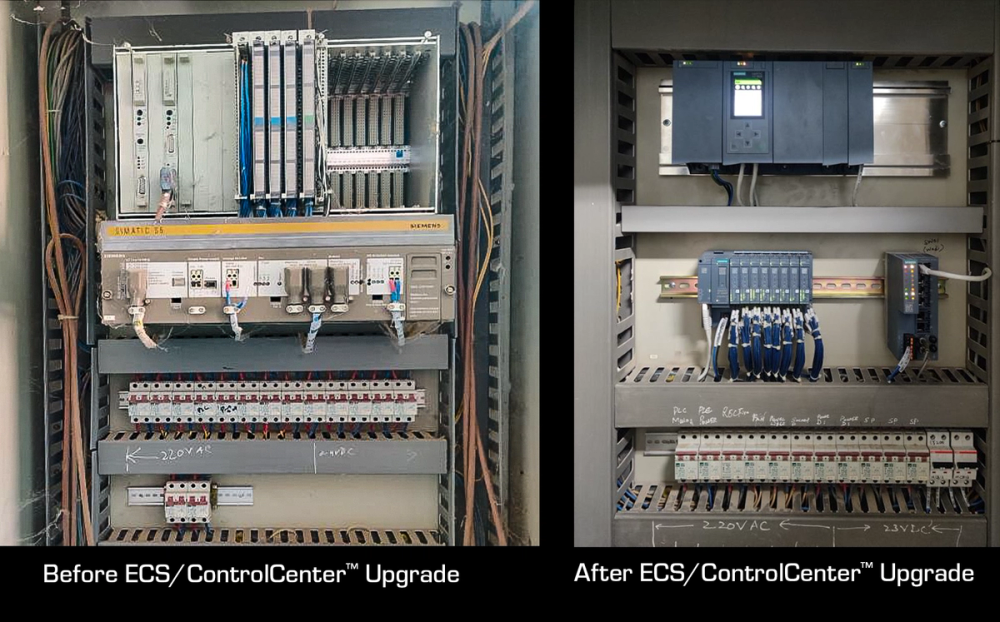

Outdated control systems can significantly slow down operations, drive up costs, and lead to unexpected shutdowns. This was exactly the challenge facing SPCC (Southern Province Cement Company) Bisha's water treatment plant. Their aging automation system had become increasingly difficult to maintain, plagued by obsolete components and dwindling technical support. The urgent need for a reliable, fast upgrade became undeniable.

The Problem: An Outdated System

For years, Bisha's water plant depended on an obsolete control system. However, as technology advanced, maintaining this outdated infrastructure grew both costly and risky. The scarcity of replacement parts meant even minor technical issues could escalate into major operational problems.

The breakthrough came during routine discussions when plant managers realized FLSmidth Cement, already successfully managing automation at Bisha's cement plant, might have the solution. FLSmidth Cement’s proven ECS/ControlCenter system, combined with an established partnership, made Bisha the ideal choice for this critical upgrade.

Bisha's requirements were straightforward yet crucial: real-time performance monitoring to enhance visibility, advanced diagnostics to prevent downtime, and comprehensive reporting capabilities for better decision-making - all implemented with minimal disruptions to ongoing operations.

The Solution: A Smarter Control System

FLSmidth's ECS/ControlCenter, while primarily designed for cement plants, proved equally effective for water treatment applications. The system featured a modern, user-friendly control interface based on ACESYS v8 (Structured Programming Library) standards. Custom configurations mirrored the familiar old system layout, ensuring operators could transition with minimal disruption. Perhaps most importantly, the real-time simulation capability allowed for thorough, risk-free operator training before the actual system went live.

Nissar Hussain – Head of Projects Execution

The Upgrade: Fast, Smooth, and On Time

The implementation showcased exceptional collaboration between FLSmidth Cement and Bisha's team. Engineers developed tailored control software specifically designed for the plant's unique requirements. They systematically replaced outdated hardware components with modern, reliable alternatives and installed redundant backup servers to eliminate single points of failure. Remarkably, all testing and commissioning occurred seamlessly within the planned maintenance window, avoiding any operational delays.

The Results: A More Reliable Plant

The project's success exceeded expectations. The upgrade completed precisely on schedule without a single interruption to water treatment operations. Plant personnel now benefit from significantly improved process visibility and control, while the risks associated with the obsolete system have been completely eliminated. Furthermore, the new infrastructure provides a scalable platform ready to accommodate future expansion needs.

Why Choose FLSmidth Cement?

What set FLSmidth Cement apart wasn't just their advanced technology, but their comprehensive approach to ensuring perfect implementation. Their deep industry expertise, engineering excellence, and unwavering focus on customer requirements transformed this upgrade into a resounding success. Today, Bisha's water treatment plant operates more efficiently than ever, with robust systems that will serve reliably for years to come.

For operations seeking a trustworthy partner for their automation upgrades, FLSmidth Cement stands ready to deliver.