article

Precision Feeding in Cement Production

As the cement industry evolves to meet environmental challenges, one trend is clear: more variable feedstock requires more precise processes. In the pyro process, where alternative fuels play an increasingly important role in lowering carbon emissions, it is the role of materials handling solutions like the PFISTER® Rotor Weighfeeder to ensure precise and stable dosing of both alternative and fossil fuels to avoid volatility in the kiln and maintain consistent clinker quality.

PFISTER ® rotor weighfeeders have been the go-to solution for cement plants implementing or expanding their alternative fuels feed for decades, with more than 380 PFISTER® TRW-S/D Rotor Weighfeeders installed to support alternative fuel utilisation since 1997. With advances in technology, they are now increasingly sought after to also reduce fossil fuel use to a minimum via the FEEDflex™ upgrade at the DRW Rotor Weighfeeders (coal).

Precision dosing for fuel, raw meal and low-carbon cement mixes

All PFISTER® rotor weighfeeders operate on a gravimetric dosing principle that is designed for precision and responsiveness – particularly important for alternative fuels, where feedstock can vary so widely. Material is extracted from storage and carried in rotor chambers from inlet to outlet. The rotor is supported on an eccentric axis that allows the system to continuously measure the mass of material in transit via a single-point load cell. This real-time weight data, combined with rotor position, is used by the feed controller to calculate and adjust the optimal rotor speed. The heavier the load, the slower the speed; the lighter it is, the quicker it moves. ProsCon® prospective control enables the system to anticipate and respond to material fluctuations almost instantly, providing stable operation even under variable conditions. This balance of mechanical simplicity and electronic intelligence makes it particularly effective for dosing a wide range of alternative fuels with high precision. The same principle applies to raw meal dosing, low carbon cement mixes, and fossil fuels.

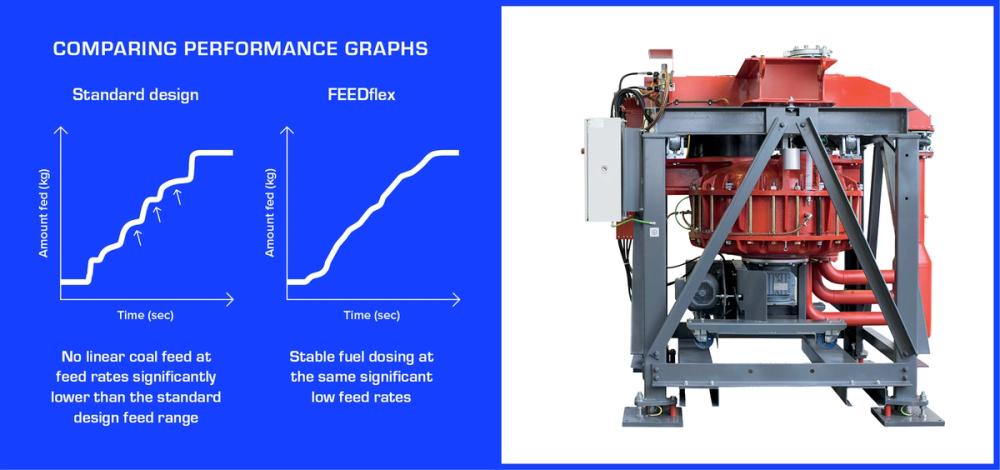

One of the challenges with fossil fuels, however, is that they are still necessary, but cement producers want to drastically limit their use – which is beyond the capability of most feeding/dosing solutions. The FEEDflex™ technology was invented to answer this challenge. It is an upgrade to the PFISTER ® DRW Rotor Weighfeeder that enables a feed range of 1:100, allowing cement producers to maintain a minimal feed of coal or pet coke to the burner – as little as 60 kg/hour (e.g. DRW 4.10 size) – without affecting the maximum feed rate of the feeder. Companies such as Mannok in Ireland have put the FEEDflex to use in their calciner system, which is capable of running at 100% alternative fuels, but which sometimes requires the introduction of coal for start-up or if alternative fuels supplies run low. The FEEDflex gives cement producers the flexibility to introduce more coal when they need to and keep it to a minimum at all other times without pulsations and related CO spikes.

Handling non-free-flowing and compressible fuels

Ensuring optimum fuel dosing and kiln stability begins with optimising the fuel mix. Understanding the various factors at play here, we engineered a purpose-built alternative fuels storage and reclaim solution that can cope with all kinds of alternative fuels, including high-moisture and sticky municipal solid waste (MSW) or refuse-derived fuels (RDF) without succumbing to blockages that could disrupt the process.

The Feedex™ overhead reclaimer storage is designed to eliminate bridging and clogging of alternative fuels. It is a combined storage and reclaim system comprising a 1.250 m³ bunker– usually made of concrete or steel – installed with a Feedex frame suspended on marine-quality hoisting chains and powered by dust-proof, fan-less motors. This is a low energy system, built to be easy to clean and maintain, with a simultaneous feeding and extraction capacity of up to 600 m3/hr. Scrapers move continuously to distribute/stack the material in the bunker, preventing agglomeration and optimising fuel blending to improve stability in the pyro process. 3, 4, 5 or more of the Feedex OHR can be installed side by side to enable customers a preselection of the AF mixture they want to burn.

Improving flexibility in fuel strategy

With so many different fuel types on the market and vastly different infrastructures available in different regions, embarking on an alternative fuels project can be rife with uncertainties. To ease the transition to new fuel types, the PFISTER® AF Starter Kit – a Plug and Play solution – allows cement plants to ‘test drive’ AF utilisation and speed up the permissions process, while also offering speedy ROI, quick delivery, fast running time and easy maintenance.

Smarter bulk material handling for a leaner cement industry

Achieving the cement industry’s ambitious environmental goals requires a joined-up approach that stretches from alternative fuel supply chains right through to regulatory changes that enable and encourage low-carbon cement mixes. Along the way, materials handling systems will have a key role to play in ensuring that cement quality is not compromised by the introduction of new fuels and raw materials. Precision dosing technology, assisted by advanced automation systems and enhanced by an attitude of innovation, will be critical to ensuring both process uptime and clinker quality.

Though the PFISTER® rotor weighfeeder has been a reliable industry workhorse for decades, it should not be overlooked as an ally on the road to Net Zero – nor will we stop seeking ways to use this and other technology to enhance sustainability across the cement process.

This article orginally appeared in the Summer 2025 edition of Dry Bulk Materials Review