Reliable bevel gears deliver smooth performance for your equipment

Bevel gears with high-function in your gear units – and more

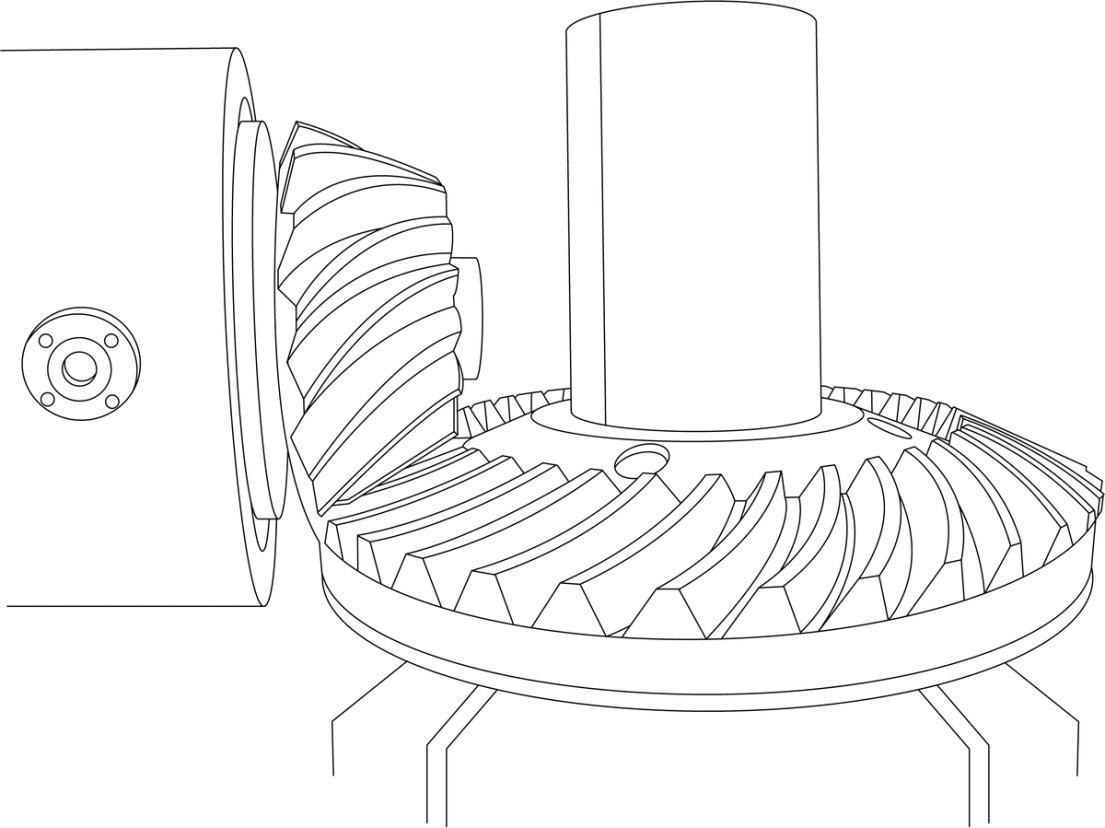

We produce well-made, durable bevel gears for our own MAAG® GEAR line of products, as replacement parts, or as power transmission components in mining equipment like gyratory or cone crushers. Whether used in gear units for vertical mills, as part of roller press drives or within the transmission gear for bucket wheel excavators or belt conveyors, bevel gears are an important part of gearboxes – and we deliver the highest quality in these crucial components. With over 130 years of experience with heavy-duty equipment fabrication, we have the rigorous quality standards, exceptional manufacturing processes and engineering insight to produce the highest quality bevel gears – giving you confidence in the components you employ in your plants. Modern production – and diverse toothing options Our state-of the-art manufacturing facility in Poland has the most advanced machines for manufacturing gear bevel gears in-house. Using our unique technology to produce high-quality bevel gears, we ensure consistent quality, reduce costs and increase the convenience factor. We manufacture gears and bevel gears for a range of applications in the cement and minerals industry – ensuring that you get the highest quality products that are customised to your specifications. Depending on your needs, we can manufacture bevel gears with different tooth geometries for heavy-duty applications. Straight and helical toothing are the simplest designs for bevel gears. Limited to small power and lower circumferential speed, bevel gears with straight or helical toothing are often used in crushers. Heavy-duty bevel gears for applications with high-torque and greater peripheral speed are built with curved tooth geometry. Palloid and cyclo-palloid gearing provides optimal roll-over behaviour – reducing noise and guaranteeing smooth operation. Bevel gear sets with palloid and cyclo-palloid gearing are well-suited for applications in vertical roller mill drives. MAAG® GEAR bevel gear sets are hard finished as necessary using a skiving process. The digital drive technology enables top-notch precisions and repeatability.

Bevel gears that last – built specifically for your needs

Custom-made – without long lead time

Designed for longevity and high performance

High technological production expertise

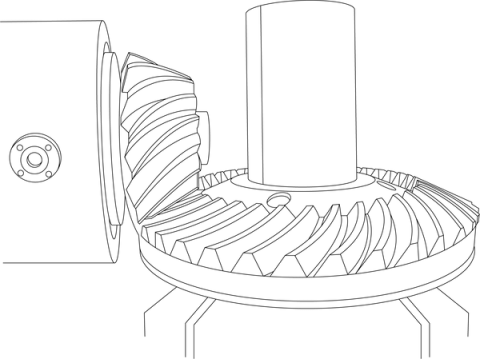

Bevel gear sets are a special form of gear design where the input and output axes have a common intersection. The angle between both axes is usually rectangular. Bevel gears often serve as speed reducers in heavy-duty applications, meaning that the input shaft acts as the bevel pinion, while the bevel wheel forms the output shaft.