Adaptable heavy-duty gear unit gives strong results across industries

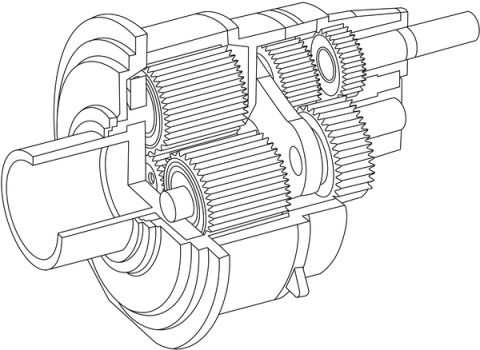

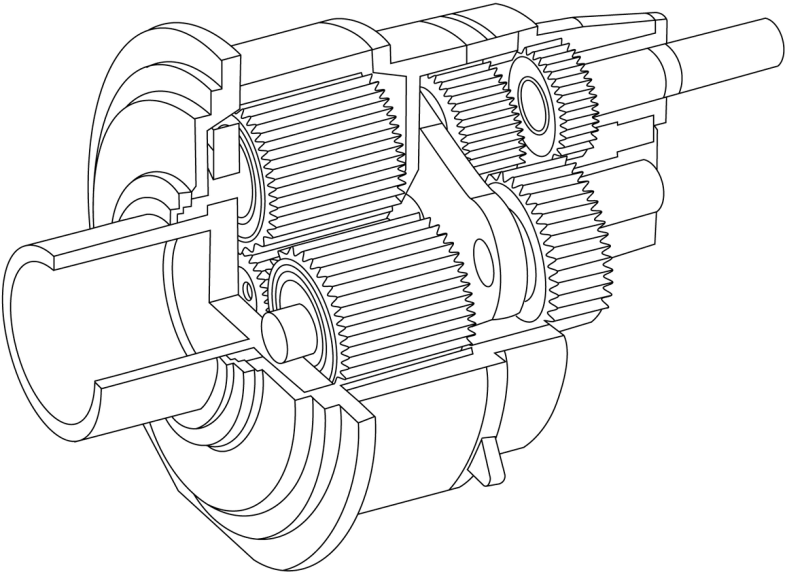

With the flexibility to work in nearly every heavy-duty application, our MAAG® GEAR PPU-C planetary gear unit is proven technology that gives you results. The compact, modular unit uses an exceptionally efficient tooth arrangement for maximum power transmission in ball mills, while low part variation simplifies servicing.

Heavy-duty performance from our compact planetary gear unit

Widely-used in many heavy-duty applications like roller presses, ball mills and sugar cane processing, the flexible input stage of our MAAG® GEAR PPU-C Gear Unit allows this three-stage gearbox to easily adapt to different applications in a variety of industries.

Improving a proven technology

First developed in 1987 for roller presses in the cement and mining industries, we redesigned our PPU-C Gear Unit in 2013. Through the redesign, we made the MAAG® GEAR PPU-C Gear Unit more cost effective and expanded its use for heavy-duty applications into mining, food production and other sectors. The PPU-C unit now drives small ball mills in a range of industries – far beyond the original scope of cement production.

With an eye to enhancing the proven technology of the original design, the redesign resulted in a compact and modular gear unit – with even better functionality. The tooth geometry follows the well-proven MAAG® GEAR standard and was recalculated according to the latest ISO and AGMA standards. This guarantees optimum load distribution across the teeth, generating maximum power transmission.

The ring gears of both planetary stages also directly form the casing. This design feature allows the gear ratio of each single planetary stage to increase, while still maintaining the same outer diameter for the casing. The result is a lighter and smaller gear unit. In addition to scaling down size and weight, we also trimmed the diversity of parts in the gear unit by 20%. A lower diversity of parts makes the MAAG® GEAR PPU-C more modular and flexible – and lowers costs.

Easy handling and high adaptability

The compact design of our heavy-duty PPU-C Gear Unit simplifies transport and reduces assembly time. The reduced diversity of parts also leads to less complicated maintenance.

Fewer different spare parts for the PPU-C Gear Unit mean lower-cost part management, as well as less space needed for part storage. We ensure the standardised parts are readily available throughout the life of the unit.

The flexibility of our PPU-C Gear Unit lets you optimise it to suit your heavy-duty application, adapting to the power you require, as well as the speed of your motor and mill. The highly standardised, modular concept of our PPU-C Gear Unit also means that you can make ratio adjustments without impacting delivery times.

Alongside classic ball mill applications, the flexibility of our planetary MAAG® GEAR PPU-C Gear Unit makes it ideal for other heavy-duty uses such as:

drive units for roller presses, kiln drives, in combination with a spur gear for sugar cane presses, and working in tandem with a spur gear in many other heavy-duty applications.

A smaller and lighter gear unit – with more flexibility and longevity

01

Heavy-duty performance in a smaller and lighter design

Following the 2013 redesign, our MAAG® GEAR PPU-C Gear Unit delivers greater functionally with a smaller footprint and less weight. Not only does the compact design give you greater flexibility in terms of configuration and use in different heavy-duty applications, it also simplifies transport and reduces assembly time

02

Modular flexibility adapts to your unique circumstances and needs

Our MAAG® GEAR PPU-C Gear Unit is based on a modular concept, with different input stage designs that accommodate many different applications and industries. The bearing arrangement and gearing design allow for both senses of rotation.

03

Manufactured for a long operating life

We use the latest machines and manufacturing processes, ensuring all parts are fit-for-use and free from defects. The toothed components are produced in-house to the strictest quality standards, using case-hardened and heat-treated steel. This in-house heat treatment gives us complete control over the hardening processes and material properties – and it gives you confidence in the durability and reliability of the MAAG® GEAR PPU-C Gear Unit and its components.

04

Easy maintenance with standardised parts

With only five different types of bearings in our MAAG® GEAR PPU-C Gear Unit and the part standardisation resulting from the 2013 redesign, it’s easy for you to have the spare parts you need on hand. The need for fewer types of parts improves maintenance efficiency, as does the removable input stage.

Top marks for easy upkeep from an adaptable, heavy-duty gear unit

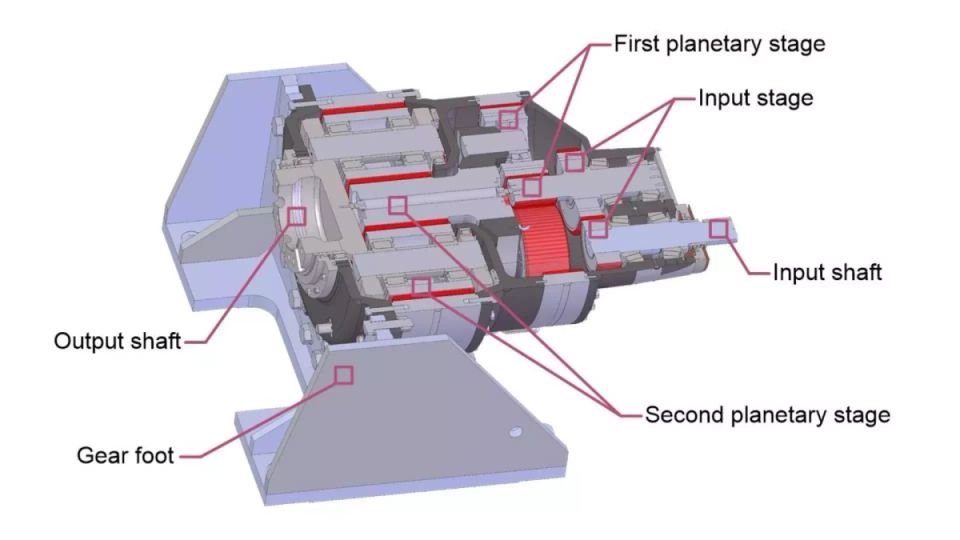

Our planetary MAAG® GEAR PPU-C Gear Unit for small ball mills comprises the: gearbox with foot, high and low speed coupling, lubrication unit, auxiliary drive, and optional water injection. The three-stage gear unit has a customisable input stage and two planetary stages. Our high-quality materials and a bearing lifetime in excess of 100,000 operating hours contribute to the longevity and ease of maintenance of the heavy-duty PPU-C Gear Unit.

Components deliver application flexibility

The input gear stage of our MAAG® GEAR PPU-C Gear Unit is available ether in spur or bevel gear arrangement. This give you a high degree of flexibility, as ratio requirements can be fulfilled by simply changing the wheels of the input stage, letting you use it for ball mills, kilns and other heavy-duty applications.

Our planetary PPU-C Gear Unit optimises lubrication oil consumption, with the unit casing itself also serving as an oil circulation tank. The ability to deliver the ideal oil level reduces churning losses and improves your efficiency. The scope of supply for the PPU-C Gear Unit includes the oil supply unit with low-pressure pump, double oil filter and oil cooler. For roller press drives, you also have the option of a cost-effective, single oil unit that lubricates both gear units

Simple operation with the auxiliary drive

The auxiliary drive allows you to slowly turn the ball mill to evenly cool it or for maintenance tasks. It is equipped with a small planetary gearbox and a fluid coupling to minimize torque peak during start up and smoothly accelerate the mill. The overrunning clutch between the auxiliary drive and the main motor automatically disengages the auxiliary drive when the main motor is started.

Beyond a basic condition monitoring system

All of our gear units are equipped with unparalleled condition monitoring sensors. Normally, these types of sensors keep an eye on critical operating parameters like bearing temperatures, casing vibrations, etc. and trigger a mill shutdown in the case of exceedances.

Our condition monitoring system does much more. It lets you set up condition-based preventive maintenance that uses continuous monitoring and data analysis to detect wear and tear at an early stage. With this enhanced information, we help you plan maintenance and servicing in advance – reducing downtime and keeping your plant running smoothly.